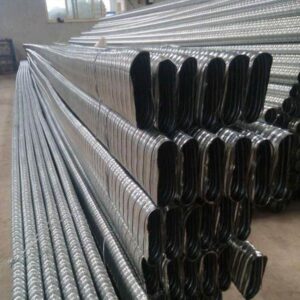

Engineers rely on post tension ducts (PT ducts) to enhance structural integrity in high-stress concrete applications. These corrugated sheathing systems protect prestressing tendons while enabling efficient grout injection, ensuring long-term durability.

Applications

- Bridges & Highways: Resist dynamic loads and seismic forces.

- High-Rise Buildings: Reduce slab thickness while maintaining strength.

- Parking Structures: Mitigate cracking from heavy cyclic loads.

Engineering Solutions

- Corrosion Protection: HDPE/steel hybrid designs prevent tendon degradation.

- Grout Compatibility: Smooth inner lining ensures void-free grout flow.

- Modular Joints: Pre-fabricated couplers reduce on-site labor by 30%.

The key benefits and features for Corrugated Ducts

☆ Wide range of diameter available (ID 50mm to ID 120mm).

☆ Quantity as per the site requirement can be manufactured.

☆ Easy benchmarking and thus production schedule.

☆ Customer friendly – Bendable and can be cut as per customer requirement.

☆ Ease of placement at site: Durable and tough.

☆ Corrosion protection with hot dip zinc coating.

Smart Functionality

- Embedded Sensors: IoT-enabled ducts monitor tendon tension in real-time (optional).

- RFID Tagging: Track installation progress via digital logs.

Technical Notes

- Installation Tip: Use helical spacers to maintain duct alignment during concrete pour.

- Grouting Alert: Low-viscosity grouts (≤12 sec flow time) recommended for narrow ducts.

Why Choose Us?

- Certified Quality: Third-party tested to exceed ASTM/EN standards.

- Customization: Tailor duct profiles for complex geometries.

- Global Support: 24/7 technical advisory from licensed engineers.