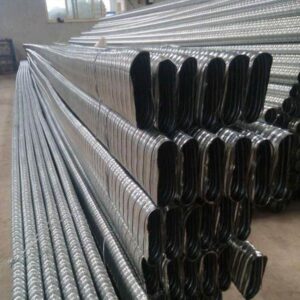

Prestressed Corrugated Metal Ducts (PCMD): The Ultimate Solution for Modern Construction

Application Scenarios

Prestressed Corrugated Metal Ducts (PCMD) are essential in post-tensioning systems for bridges, high-rise buildings, parking structures, and nuclear containment vessels. These high-performance conduits, sometimes called PT Ducts, provide superior protection for tensioning tendons in concrete structures.

Technical Parameters

- Material: Galvanized steel (standard) or stainless steel (premium)

- Diameter range: 50mm to 300mm

- Corrugation depth: 1.5-3.0mm

- Wall thickness: 0.3-1.2mm

- Working pressure: Up to 2.5MPa

- Temperature range: -40°C to +120°C

Key Features

- Corrosion resistance: Hot-dip galvanized coating (minimum 100μm)

- Flexibility: 180° bending capability without kinking

- Durability: 50+ year service life in most environments

- Friction reduction: Optimized corrugation pattern reduces tendon friction by 30% compared to smooth ducts

Certifications & Standards

- ISO 9001:2015 certified manufacturing

- Complies with EN 523/524, ASTM A416, and GB/T 5224 standards

- Third-party tested by TÜV SÜD and Lloyd’s Register

Project Case Studies

- Hong Kong-Zhuhai-Macao Bridge: Used 12km of 200mm PCMD in the main span

- Shanghai Tower: Implemented 8,000+ meters of stainless steel PCMD for seismic protection

Installation & Replacement

Prestressed Corrugated Metal Ducts are installed before concrete pouring using specialized spacers. Replacement requires concrete cutting and should only be performed by certified technicians.

Maintenance Guidelines

- Annual visual inspections for corrosion

- Magnetic particle testing every 5 years

- Grout void detection using ultrasonic testing

Critical Considerations

- Always use compatible grout materials

- Maintain minimum 50mm concrete cover

- Avoid welding near installed PCMD

Engineering Insights

From our 20 years of field experience:

- Stainless steel PCMD performs better in marine environments

- Proper grout filling prevents 90% of maintenance issues

FAQ Section

Q: Can PCMD be used in curved applications? A: Yes, our corrugated design allows for smooth curvature up to R=3m.

Q: What’s the lead time for custom sizes? A: Typically 4-6 weeks for non-standard diameters.

Current Promotions

- 15% discount on orders over 5,000 meters (valid until 2025-12-31)

- Free technical training with purchases exceeding 10,000 meters

Prestressed Corrugated Metal Ducts remain the industry gold standard for durable, high-performance post-tensioning systems. Contact our engineering team today for project-specific solutions.