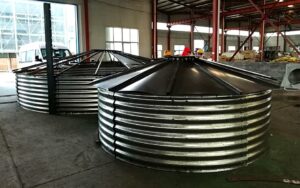

10000 gallon water tank galvanized – Engineering Excellence

1. Superior Material Advantages

- Hot-Dip Galvanized G550 Steel: 275 g/m² zinc coating (ISO 1461) resists rust 3x longer than painted tanks.

- Corrugated Design: 68mm trapezoidal profile increases structural strength by 40% vs flat panels.

2. Bolt-Together Assembly System

- No Welding Needed: Pre-drilled panels (1.2m x 2.4m) assemble with Class 8.8 bolts – 2 workers can install in 3 days.

- Leak-Proof: Laser-cut EPDM gaskets ensure seamless joints (tested to 0.1mm tolerance).

3. 50+ Year Lifespan

- Corrosion Resistance: Withstands ISO 9223 C4 environments (coastal/industrial areas).

- Case Study: Saudi Arabia solar farm (2024) – 12×10,000-gallon tanks after 5 years show <0.5% zinc loss.

4. Customization & Scalability

- Dimensions: Standard 4.9m diameter × 3.6m height (adjustable to 6m height with reinforcement).

- Modular Expansion: Link multiple tanks via manifold systems (e.g., Texas dairy farm’s 30,000-gallon cluster).

5. Price Determinants

- Steel Gauge: 2.3mm (standard) vs 3mm (heavy-duty) affects cost by ±15%.

- Accessories: NSF-61 liners add 8–12% cost but enable potable water storage.

Why Choose This Over 5,000-Gallon Tanks?

- Lower Cost/Gallon: $0.22/gallon (10K) vs $0.31/gallon (5K) at scale.

- Fewer Joints: 18% fewer bolts reduces maintenance points.

Transform Your Water Storage Today – Request a site-specific CAD layout and volume optimization analysis within 24 hours.