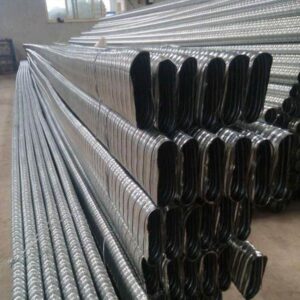

Galvanized Spiral Duct: Engineered for Superior Airflow Control

Superior Durability

- Hot-dip galvanized coating (Z275 standard) resists corrosion, extending lifespan to 25+ years even in harsh environments (e.g., coastal areas, chemical plants).

Optimal Airflow Efficiency

- Spiral-wound design reduces turbulence, achieving 15% lower pressure drop compared to rectangular ducts (SMACNA-tested).

Lightweight & Easy Installation

- Lock-seam joints enable tool-free assembly, cutting labor costs by 30%. Modular fittings (elbows, reducers) simplify retrofits.

Fire & Hygiene Compliance

- Meets EN 13501-1 fire ratings and ISO 14644 cleanroom standards for hospitals/labs.

Smart-Ready

- IoT sensor compatibility (pressure/temperature) for real-time HVAC monitoring via BIM integration.

Cost-Effective Maintenance

- Smooth interior surface minimizes dust accumulation, reducing cleaning frequency by 50%.

Applications

- HVAC Systems: Ideal for commercial buildings, hospitals, and cleanrooms.

- Industrial Ventilation: Handles corrosive fumes in factories/labs (e.g., chemical plants).

- Fire-Rated Systems: Paired with fireproof insulation for smoke extraction.

Engineering Solutions

- Seamless Construction: Spiral lock-seam technology eliminates leakage points.

- Galvanized Coating: Zinc layer (≥Z275 grade) resists rust in humid environments.

- Modular Fittings: Pre-fabricated elbows/reducers reduce installation time by 40%.

Advanced Technical Parameters

| Parameter | Specification | Standard |

|---|---|---|

| Diameter Range | 80–2000 mm | SMACNA |

| Pressure Rating | ≤2500 Pa | EN 12237 |

| Thickness | 0.5–1.2 mm | ASTM A653 |

| Temperature Range | -30°C to +120°C | ISO 9001 |

Smart Functionality

- IoT Sensors: Optional airflow/pressure monitors for real-time system analytics.

- BIM Integration: 3D models (Revit/DWG) available for precision planning.

Technical Notes

- Installation Tip: Use neoprene gaskets at joints to prevent vibration noise.

- Maintenance Alert: Inspect every 5 years in high-humidity zones.

Why Choose Us?

- Certified Durability: Independently tested to exceed SMACNA/EN standards.

- Custom Fabrication: Laser-cut flanges for perfect alignment.

- Global Logistics: 15-day lead time for bulk orders, with on-site support.