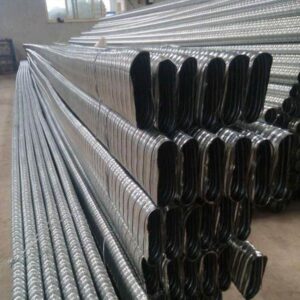

Dual Wall Pipe: Engineered Secondary Containment Solution

Application Scenarios

Critical installations requiring fail-safe protection:

- Chemical plants handling corrosive media (ASTM D1784 compliant)

- LNG transfer systems (-162°C cryogenic service)

- Pharmaceutical CIP/SIP processes (3-A Sanitary Standard)

- Underground fuel storage (EPA 40 CFR Part 280)

- Commercial storm sewers

- Tetention/detention systems

- Highway construction

- Culverts

- Grain aeration

- Agricultural pattern-tiling mains & outlets

Engineering Solutions

- Leak-Proof Design: Outer wall rated for 1.5× design pressure of inner pipe (ASME B31.3)

- Monitoring Ready: 1/4″ NPT ports every 3m for sensor integration

- Modular Assembly: Fusion-welded joints with ≤2% ovality tolerance

Advanced Technical Parameters

- Materials:

- Inner: HDPE PE100-RC (EN 12201-1)

- Outer: UV-stabilized PP (ISO 15874)

- Pressure/Temp: PN16 @ 20°C, 10bar @ 80°C (ISO 4065)

- Thermal Performance: 0.22 W/m·K conductivity (ASTM C518)

Application Cases

- Oil Refinery Expansion: 2km DN200 system detected 0.5L/min leak within 15s

- Wastewater Plant: 10-year corrosion-free operation in pH2-12 environment

Common Technical Questions

- Q: Minimum bend radius?

A: 25× pipe OD (per EN 13476-3) - Q: Leak detection sensitivity?

A: 0.1L/min with pressure decay method

Competitive Advantages

- Certified: CRN, PED, and AD2000-W0 approvals

- Digital Twin: RFID-tagged spools with 3D installation guides

- Testing Protocol: 100% hydrostatic test @ 1.5× MAWP