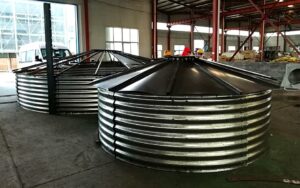

Agricultural Applications

Corrugated steel grain storage tanks serve critical roles in:

- Commercial Farming: Wheat/maize storage (100-50,000 metric ton capacity)

- Seed Processing: Climate-controlled seed banks (RH <65%)

- Organic Storage: FDA-compliant food-grade galvanization

Structural Advantages

Grain-Specific Engineering

- Corrugated Panels: 50% greater buckling resistance vs flat steel (ASABE EP433.5)

- Ventilation Systems: Optional CCANZ-certified aeration floors

- Material Science: 275g/m² G90 galvanization (ASTM A653)

Technical Solutions

Custom Configurations

- Diameter Range: 5m-40m (EN 1993-4-2 Class 2)

- Eave Heights: 6m-30m with stiffener rings

- Discharge Options: 30°-60° cone bottoms (DIN 1055-6)

Performance Parameters

SpecificationRangeStandardWall Thickness1.6-4.0mmAS 3774Wind Rating60m/s (Cat 3 hurricane)ASCE 7-22Thermal Conductivity0.5W/m·K (insulated models)ISO 8301

Global Installations

- 50,000MT wheat storage for Cargill (Argentina) – 2023

- 120-unit rice bin complex in Vietnam – 2022

- -40°C barley storage in Canada – 2021

Engineering FAQs

Q: Dust explosion prevention measures?

A: IP65-rated explosion vents (NFPA 68) + earthing systems

Q: Maximum grain pressure capacity?

A: 12kPa lateral / 20kPa vertical (EN 1991-4)

Why Our Corrugated Steel Grain Storage Tanks?

- Digital Grain Monitoring: IoT moisture/temp sensors

- Certified Safety: ATEX Zone 22 compliance

- 30-Year Warranty: Backed by TÜV Rheinland certification

Note: “Bolted grain bins” refers to the same product category in agricultural contexts.