Prestressed corrugated duct sizes: technical specifications and selection guide

Download the complete prestressed corrugated duct sizes chart.

1. Prestressed Corrugated Metal Ducts

Standard Sizes & Applications:

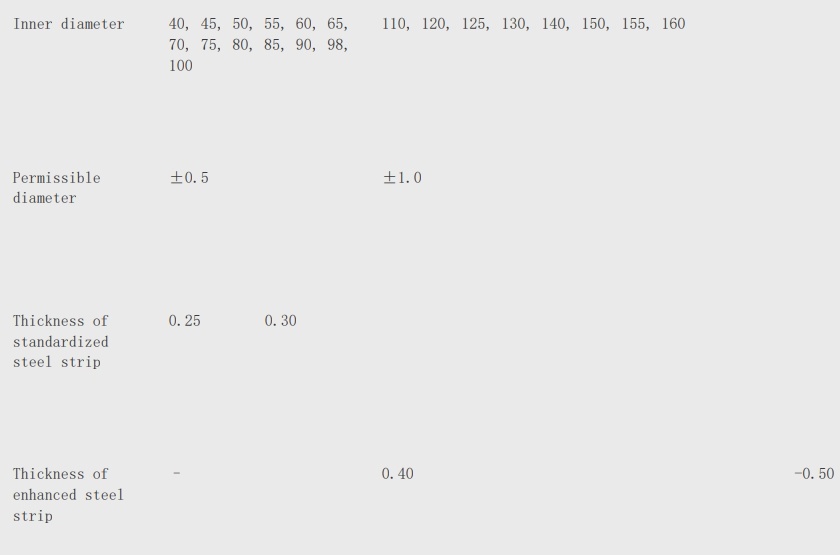

- Diameter Range: 50mm to 300mm (post-tensioning tendons)

- Wall Thickness: 0.25mm to 1.0mm (galvanized steel or stainless steel)

- Corrugation Pitch: 15mm to 30mm (spiral or annular designs)

Case Example:

Hong Kong-Zhuhai-Macao Bridge used 120mm prestressed steel ducts with 0.5mm galvanized coating for corrosion resistance in marine environments.

2. Plastic Corrugated Duct (HDPE/PP)

Common Dimensions:

- Internal Diameter: 40mm to 250mm (for grout injection)

- Wall Thickness: 1.5mm to 4.0mm (smooth or ribbed interior)

- Pressure Rating: PN6 to PN16 (for high-pressure grouting)

Key Feature:

Lightweight & chemically inert, ideal for aggressive soil conditions (e.g., wastewater plants).

3. Dual Wall Corrugated Pipe

Structural Specifications:

- Outer Diameter: 100mm to 600mm (for drainage & cable conduits)

- Inner Smooth Layer: 1.0mm to 3.0mm thickness

- Stiffness Class: SN4 to SN16 (kN/m²)

Project Reference:

London Crossrail employed 400mm dual-wall HDPE ducts with SN8 stiffness for underground cable protection.

Selection Criteria for Engineers

- Load Requirements:

- Verify axial & radial strength per EN 524 (Europe) or ASTM F2160 (US)

- Corrosion Resistance:

- Galvanized steel for neutral soils

- HDPE for acidic/alkaline conditions

- Installation Factors:

- Minimum bending radius (≥30× pipe diameter)

- Joint sealing (heat fusion for plastics, threaded couplers for metal)

Comparative Summary

TypeBest ForMax Temp.LifespanMetal DuctHigh-stress post-tensioning150°C50+ yearsPlastic DuctChemical resistance80°C30 yearsDual Wall PipeUnderground utilities60°C50 years

All data complies with ISO 9001, ASTM, and EN standards.