1. Project Requirements Assessment

Hydraulic Capacity Calculation

The peak flow rate (Q) should be calculated using Manning’s equation:

Q = (1.486/n) × A × R²/³ × S¹/² Where:

- n = Manning’s roughness coefficient (0.012-0.024 for corrugated steel)

- A = Cross-sectional area

- R = Hydraulic radius

- S = Slope gradient

Soil Condition Analysis

For corrosive soils (pH<5 or resistivity<1000 ohm-cm), specify Type 2 aluminized coating per ASTM A929.

Load Requirements

Example: For highway applications with H-20 loading (16,000kg wheel load), use:

- 2.67mm thickness for <1m cover depth

- 3.43mm thickness for 1-3m cover

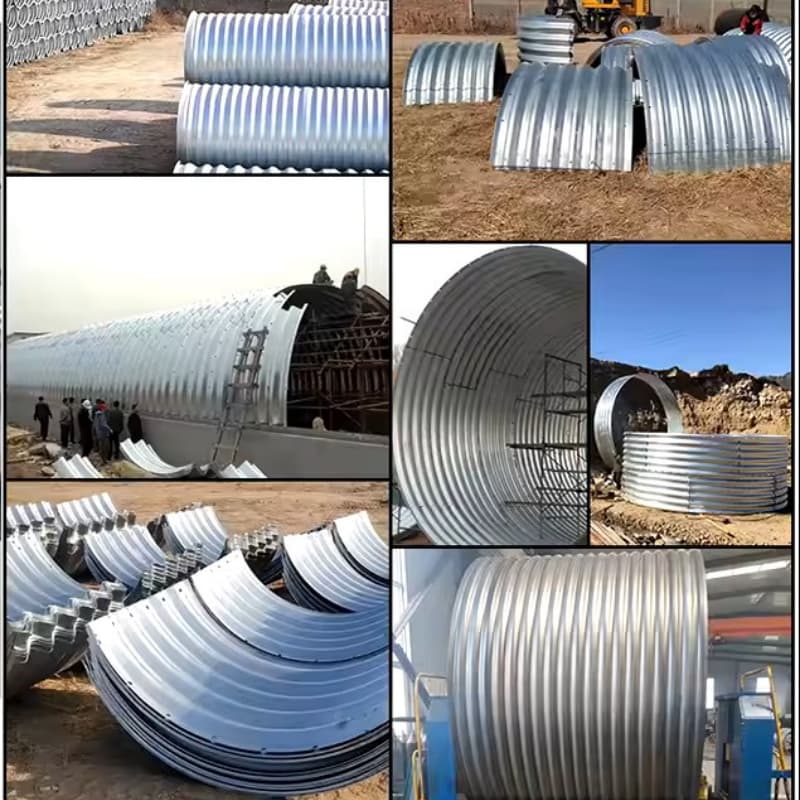

2. Material Specifications

ParameterStandard OptionsRecommendationCoating TypeGalvanized (ASTM A123), Aluminized Type 2Coastal: AluminizedSteel Thickness1.63mm – 4.32mm (16-12 gauge)Match AASHTO Table 12-8Corrugation Profile68×13mm, 75×25mm (ASTM A760)75×25mm for high flows

3. Sizing Methodology

Hydraulic Design

Minimum diameter = √(4Q/πV) where V=2.5-4.5 m/s (max to prevent scour)

Terrain Adaptation

- Slopes >15°: Install anti-flotation anchors every 3m

- Permafrost zones: Use 150mm oversized diameter for thermal contraction

4. Corrosion Protection Comparison

MethodLifespanCost FactorClimate SuitabilityHot-Dip Galvanized30-50 yrs1.0xTemperate (AASHTO M111)Polymer Coated50-75 yrs1.8xChemical exposure areasWeathering Steel75+ yrs2.3xDry climates (ASTM A847)

Expert Tip: Dr. Emily Carson (PE) recommends: “In marine environments, combine aluminized coating with sacrificial anodes for >75 year service life.”

5. Installation Protocols

Foundation Preparation

- Compacted granular base (150mm min.) at 95% Proctor density

- Geotextile wrap required when CBR <3%

Joint Sealing

Butyl rubber gaskets (ASTM D4070) for pipes >900mm diameter

Backfill Specifications

- Zone 1: 300mm either side – 90% compaction with <12mm aggregate

- Zone 2: 85% compaction to 1.5× pipe height

Climate-Specific Considerations

- Tropical: Increase thickness by 0.5mm for 2000+ mm/yr rainfall

- Arctic: Specify ductility >20% elongation (ASTM A370)

- Desert: UV-resistant polymer coatings mandatory