Corrugated Metal Pipe Sizes Guide: Dimensional Standards and Selection Guide

Download the corrugated metal pipe sizes chart.

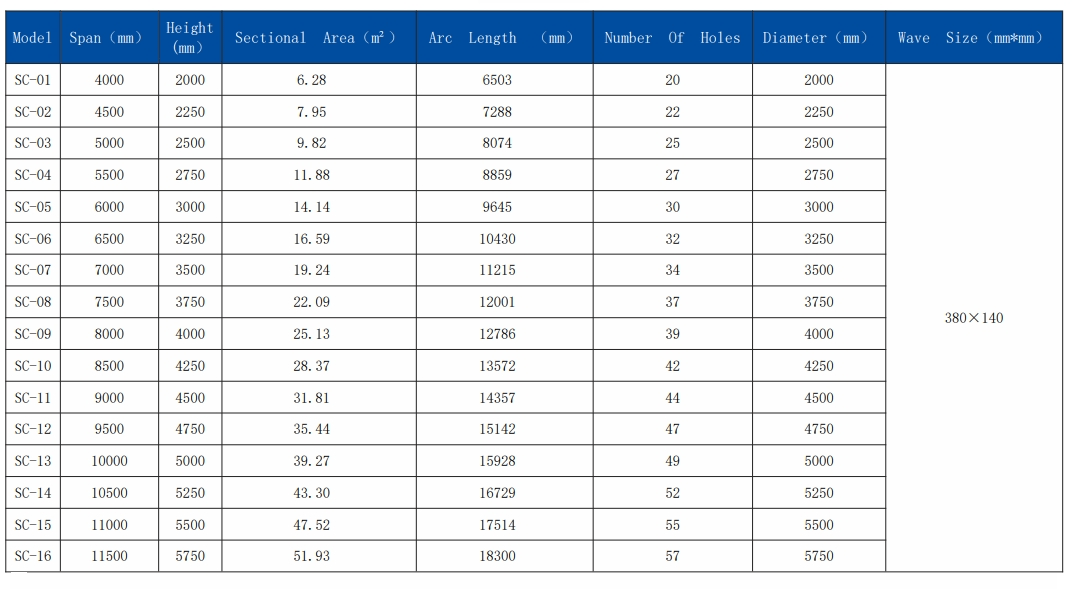

1. Corrugated Steel Arch Pipes

Standard Dimensions:

- Span Range: 8′ to 40′ (2.4m to 12.2m)

- Rise/Span Ratio: 0.5 to 0.75 (typically 0.6)

- Material Thickness: 12 GA to 1/4″ (2.7mm to 6.4mm)

Case Example:

I-94 Michigan bridge replacement used 28′ span x 18′ rise arches with 3/16″ thick galvanized steel, achieving 100-year design life with polymer coating.

2. Corrugated Steel Culvert Pipes

Common Specifications:

- Circular Diameters: 24″ to 144″ (0.6m to 3.7m)

- Elliptical Profiles: 72″x48″ to 144″x96″

- Wall Patterns:

- 2-2/3″ x 1/2″ corrugation (Type M)

- 5″ x 1″ structural plate (Type SP)

Load Capacity Data:

ASTM A796 Class III 120″ pipes withstand HS-20 loading at 15′ cover when backfilled with select granular material.

3. Metal Box Culverts

Dimensional Parameters:

- Single Cell: 6’x4′ to 20’x20′

- Multi-Cell Configs: Up to 3-cell 30′ total width

- Thickness Standards:

- 14 GA for <8′ spans

- 3/16″ for 8′-16′ spans

- 1/4″ for >16′ spans

Notable Project:

Colorado DOT’s US-36 flood channel utilized 18’x12′ aluminum box culverts with 0.188″ wall thickness, reducing weight by 35% vs steel equivalents.

Selection Considerations

Hydraulic Factors:

- Manning’s n values:

- 0.024 (smooth coatings)

- 0.033 (standard corrugations)

Structural Requirements:

- AASHTO LRFD Section 12 for live load distribution

- Minimum 1.5 safety factor for buckling resistance

Corrosion Protection:

EnvironmentCoating SystemNormal soilsG235 galvanizingCoastal areasGalfan + polymerIndustrial zones3-layer polyethylene

Installation Best Practices

- Foundation preparation:

- Minimum 95% compaction for bedding

- Geotextile separation layers in fine soils

- Joint detailing:

- 6″ minimum overlap for structural plate

- Butyl sealant for watertight applications

- Backfill requirements:

- Select granular material within pipe zone

- Lift thickness ≤12″ for proper compaction

All dimensional data conforms to ASTM A796, AASHTO M167, and CSA G401 standards.