Industrial Applications

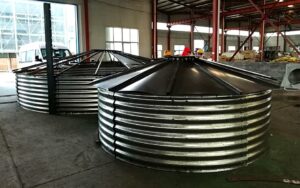

Corrugated Steel Storage Tanks provide optimal solutions for:

- Bulk water storage (potable/firefighting)

- Agricultural liquid fertilizers (NH3-proof coatings)

- Petroleum derivatives storage (API 650 Appendix J compliant)

- Wastewater buffer tanks (corrosion-resistant linings)

Engineering Advantages

Structural Design

- Galvanized steel panels (G550 AZ150, ASTM A653)

- 360° continuous corrugation for 35% greater hoop strength

- Bolted connections with EPDM gaskets (leak-tested @ 1.5x MAWP)

Key Advantages of Corrugated Steel Storage Tanks

1. Unmatched Structural Integrity

- 360° Corrugated Design: 35% greater hoop strength vs. flat panels (EN 1993-4-2)

- Seismic Resilience: Zone 4 certification (IBC 2018) with anti-buckling reinforcements

- Material Durability: 1.2-4.0mm hot-dip galvanized steel (G550 AZ150, ASTM A653)

2. Rapid Deployment & Cost Efficiency

- Modular Installation: 40% faster assembly than welded tanks (typical 5,000m³ tank: ≤8 weeks)

- Minimal Site Prep: No heavy foundation requirements (suitable for 30kPa soil bearing capacity)

3. Long-Term Corrosion Resistance

- Triple-Protection Systems:

- Hot-dip galvanized base (150g/m² zinc coating)

- Optional 3LPE/epoxy linings for chemical storage (NACE MR0175 compliant)

- 30-Year Design Life: Verified in aggressive environments (mining, coastal sites)

4. Engineering Flexibility

- Custom Configurations:

- Diameter: 3m to 30m (AWWA D103-09)

- Capacity: 50m³ to 15,000m³

- Roof Options: Aluminum dome/steel cone/floating covers (API 650 Appendix J)

5. Zero-Maintenance Operation

- Leak-Proof Joints: EPDM gaskets tested at 1.5x MAWP (-0.5 to +0.3 bar)

- Inspection Efficiency: External-only 5-year checks (vs. internal inspections for concrete tanks)

6. Sustainable Performance

- 100% Recyclable Materials: Carbon footprint reduction vs. concrete alternatives

- Relocation Capability: Bolt disassembly/reassembly without structural compromise

Custom Configurations

- Diameters: 3m to 30m (AWWA D103-09)

- Capacities: 50m³ to 15,000m³

- Roof options: Aluminum dome/steel cone/floating covers

Technical Parameters (ASTM/EN Standards)

ParameterSpecificationMaterial Thickness1.2-4.0mm (hot-dip galvanized)Design Pressure-0.5 to +0.3 bar (EN 1993-4-2)Seismic PerformanceZone 4 (IBC 2018)Coating Systems3-layer polyethylene (3LPE) or epoxy

Project References

- 12,000m³ firewater storage for petrochemical plant (Qatar)

- 8-unit 5,000m³ grain ethanol tanks (Brazil)

- 30-year service life verification at Australian mining sites

Engineering FAQs

Q: Maintenance requirements?

A: 5-year external inspection cycle (NACE SP0169)

Q: Installation timeframe?

A: 30% faster than welded tanks (typical 8-week lead for 5,000m³)

Why Our Corrugated Steel Tanks?

- Finite Element Analysis (FEA) optimized designs

- Factory-applied cathodic protection systems

- 100% dimensional compliance with AWWA D103/EN 1993

- Dedicated BIM models for integration with plant designs

Note: “Bolted steel tanks” refers to the same product category throughout this document.